Precision Machining

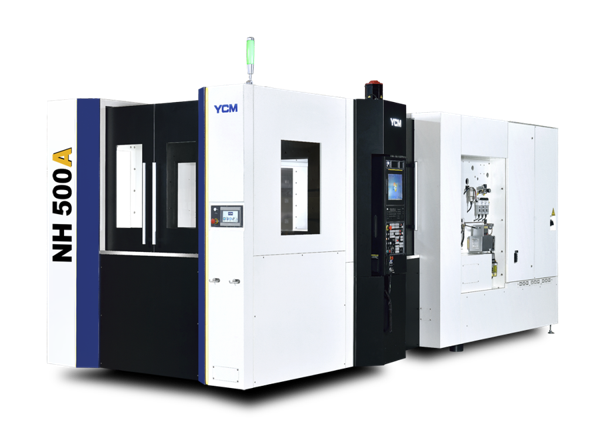

Our high precision machining capability is provided by our CNC Mills including 3-axis Leadwell V40 and Hurco VM 20, VMX 42, VMX 64, 5-axis Fryer SX-60, and YCM NH-500 Horizontal providing a wide variety envelops. We manufacture products using aluminum, steel, stainless steel, tungsten and non-metallic material, for use in high tolerance applications.

Lathe work capability through our YCM TC-16LB lathes with multi function control for fine machining process, including continuous thread creation. For custom short run or prototype part machining, our new Clark B3B three axis manual knee mill, provides high precision milling, drilling, and tapping capability. The Clark mill is equipped with a DRO for high tolerance work, and its 49” x 12” bed, is capable of larger complex part machining, without the need of repositioning.

Our precision machines provide machining capability from large metal plate finishing, to multiplane complex components, all requiring high tolerance finishing, drilling and tapping capability to meet the customer’s specifications. All machining processes are supported with a compliment of quality drill presses for drilling, honing and tapping functions.

Attention to detailed finishing and preparation is key in providing quality product. Included in the finishing process is the ability to provide bead blast, plating and painted finishes, which enhance the high quality machined & fabrication finish. All components are subjected to the highest level of quality control inspection throughout the manufacturing process.